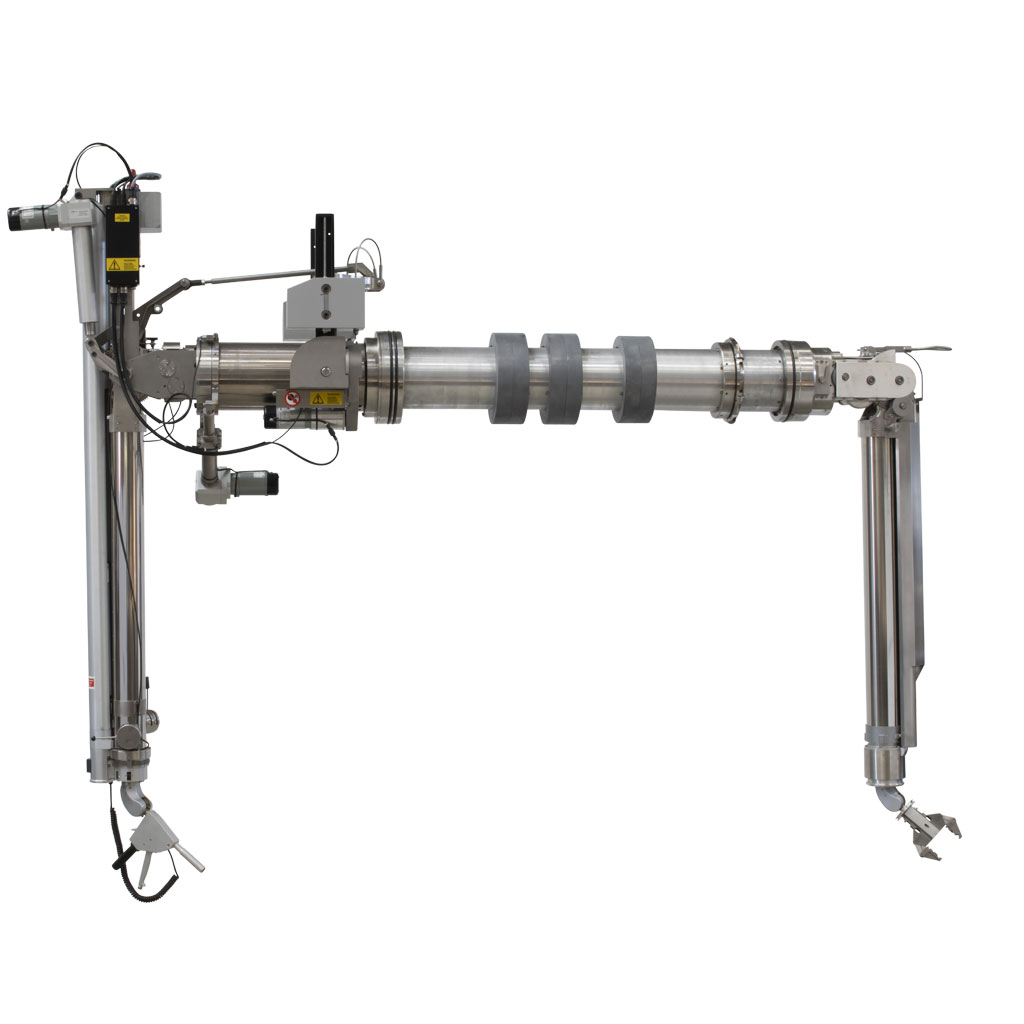

The VNE 80 and VNE 90 are low friction, gastight manipulators. They are in use in post irradiation examination laboratories and fuel element reprocessing cells. These cells require hermetic sealing for positive or negative pressure.

The telemanipulators are of modular construction and consist of four major components:

- a cold arm, which the operator controls the equipment,

- a through-wall tube,

- an extension tube and

- a hot arm inside the cell, which works in close contact with the workpiece.

All major assemblies are interchangeable throughout the range of manipulators. It means that the cold arm, the hot arm and the extension tube are separable from the through-wall tube. Consequently this will stay in the wall to maintain containment.

The manipulators are fitted with electrically powered motions on the force and aft (Y-motion), sideways (X-motion) and on the extended reach hot arm’s telescopic extension (Z-motion). To clarify, electrical adjustment allows making necessary adjustment of the working area previous to working in the confined space. Therefore the system includes motor drives to preposition the working area inside the cell. Consequently the system keeps the cold arm in the working range of the operator. On the other hand it is composed of control elements on the handle and motors. By acting on levers an off-set position between the hot arm and the cold arm is possible.

The central motion lock arrests all motions with the exception of the X-motion (which is separated by a wall mounted lock) via a central locking mechanism that incorporates an electrical cut out to the X, Y and Z drives.

Product development

The VNE 80 manipulator, in its standard version or in the optimum balance version, have been subjects of continued product development. In addition many of the new features are available as retrofittable options to existing VNE 80s to provide:

- Greater reliability

- Increased handling and range capacities

- Improved hot arm management

The VNE 90 dynamic balance manipulator incorporates both the latest product developments and manipulator options required to provide overall performance. As a consequence, the dynamic performance of the manipulator reduces the workload on the operator. Thereby it enables sensitive manipulation tasks to be effective at full reach. Additionally the modular design of the dynamic balance system is availbale as a retrofittable option to the existing range of VNE 80 telemanipulators.

Handling and special features

The standard VNE 80 and VNE 90 manipulators recommended loads are 20 kg capacity throughout the whole working area and 40 kg vertical lift by utilising the load hook.

The VNE 80 telemanipulator is available in the standard or extended reach arm versions (both interchangeable). However the VNE 90 telemanipulator is available in the extended reach version only.

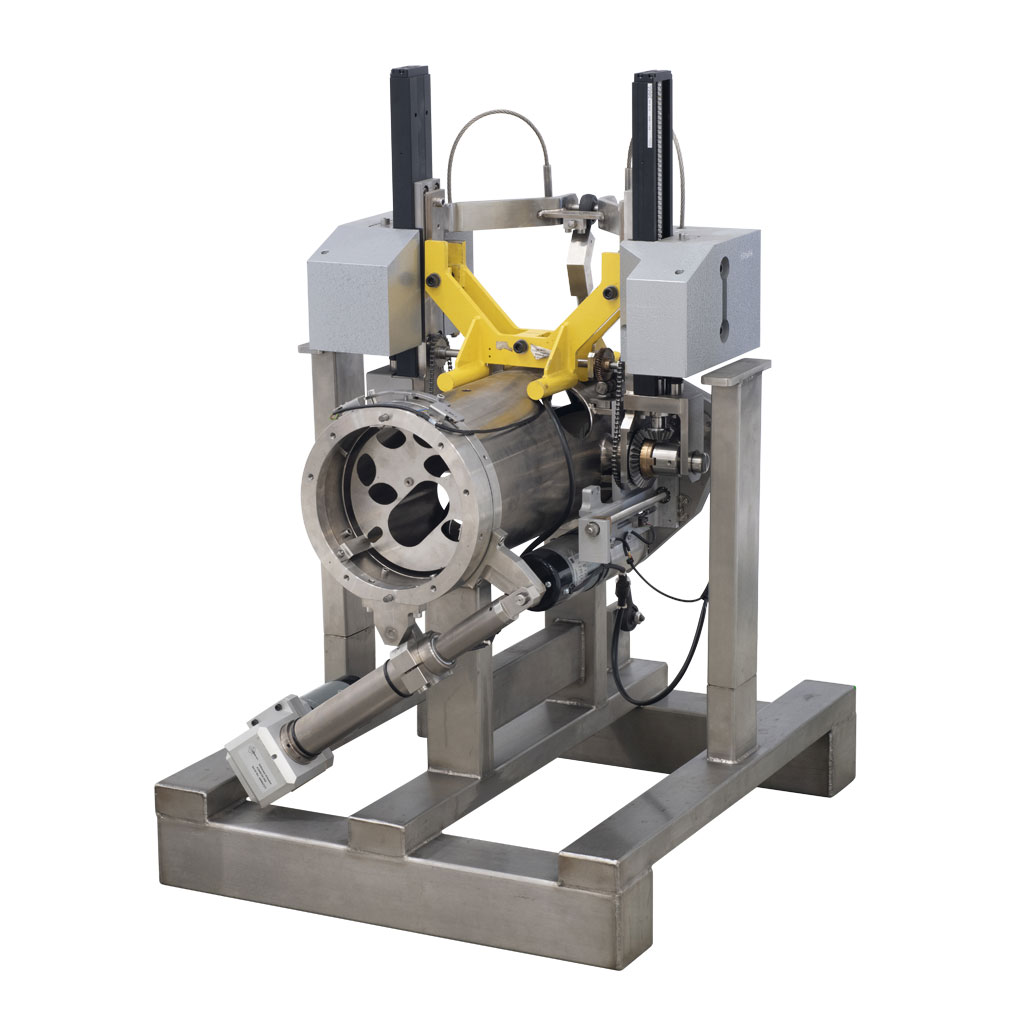

The maintenance personal disconnects the hot arm from the cold side for remote lift off in cell. The hot arm motion locks engage automatically as the hot arm disconnects in either vertical or horizontal modes. Additionally the function is compatible with existing installations. It means that the personal installs/ removes the arm conventionally from the cold side.

All motions are cable-driven with exception of the azimuth drive which is shaft-driven.

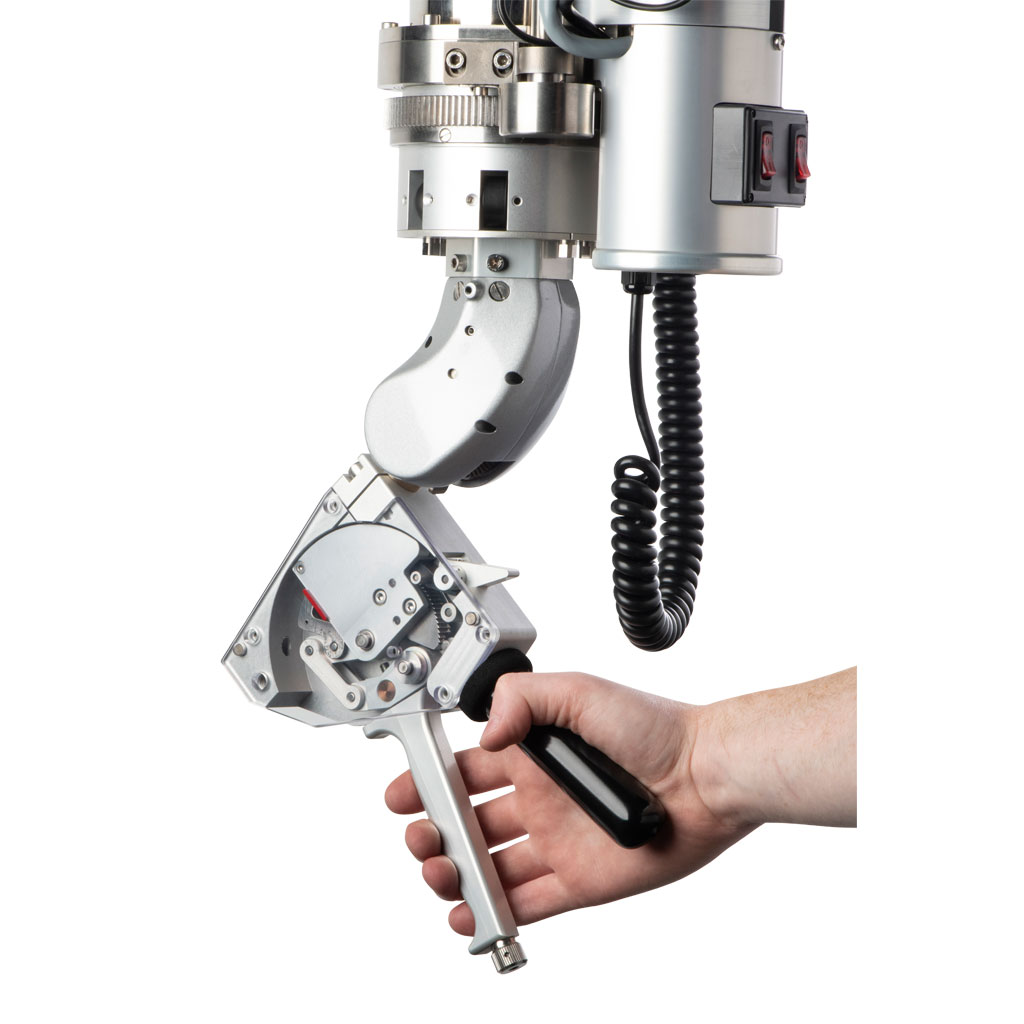

The Y-motion, Z-motion and the closing of the gripper locks stepwise by using a ratchet mechanism. In other words, the anti-reverse mechanisms act as ratchet teeth, to allow the motion to move forward only. The function is useful by working with loads that should be locked in position. Therefore, the concentration focuses on the operation. The operators speak of a relief of the burden of manipulated weight.

Materials of construction

The design of the manipulators allows ease of decontamination. Their main structural and drive components are manufactured in stainless steel.

- Gaitering Systems: hot side gaiter systems (for cold side removal). The maintenance personal removes the gaiter from the cold side.

- Part Gaiter System (for remote in cell hot arm lift off): the personal fits the gaiter to the hot arm prior to post it in the cell.

- Cold Side Bagging System: for maintaining containment during cold side removal of through tube and hot arm.

- Jaw Systems: a range of 1, 2 or 3 piece jaw assemblies are available together with the respective jaw change stations to suit the above gaiter system options.

Get more information about the Model-9 type Telemanipulator. >

Learn more about CarrsMSM-Wälischmiller. >

Get in touch with us. We will be happy to answer all your questions competently and reliably. Contact >